Wood Base Plain Particle Board

Wood Base Plain Particle Board

Particle board, a versatile engineered wood product, has gained widespread popularity in various industries for its affordability, adaptability, and eco-friendly characteristics. In this article, we delve into the world of particle board, exploring its composition, applications, benefits, and environmental considerations.

Particle board, a versatile engineered wood product, has gained widespread popularity in various industries for its affordability, adaptability, and eco-friendly characteristics. In this article, we delve into the world of particle board, exploring its composition, applications, benefits, and environmental considerations.

Composition

Particle board, also known as chipboard, consists of wood particles, such as wood chips, sawmill shavings, or sawdust, bound together using adhesive resins. These wood particles are compressed and heated to form dense panels of varying thicknesses. The result is a sturdy and economical alternative to solid wood.

Applications

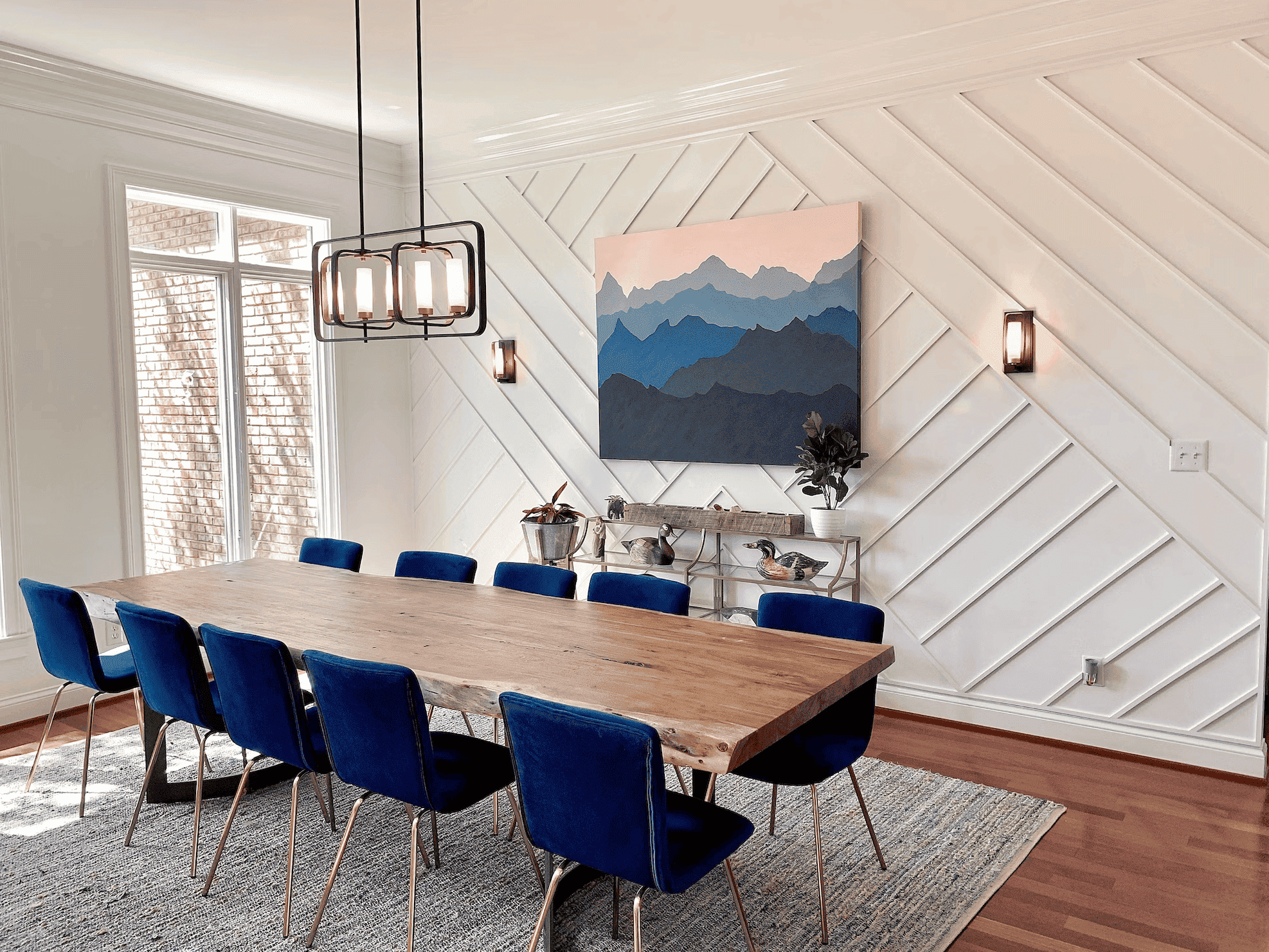

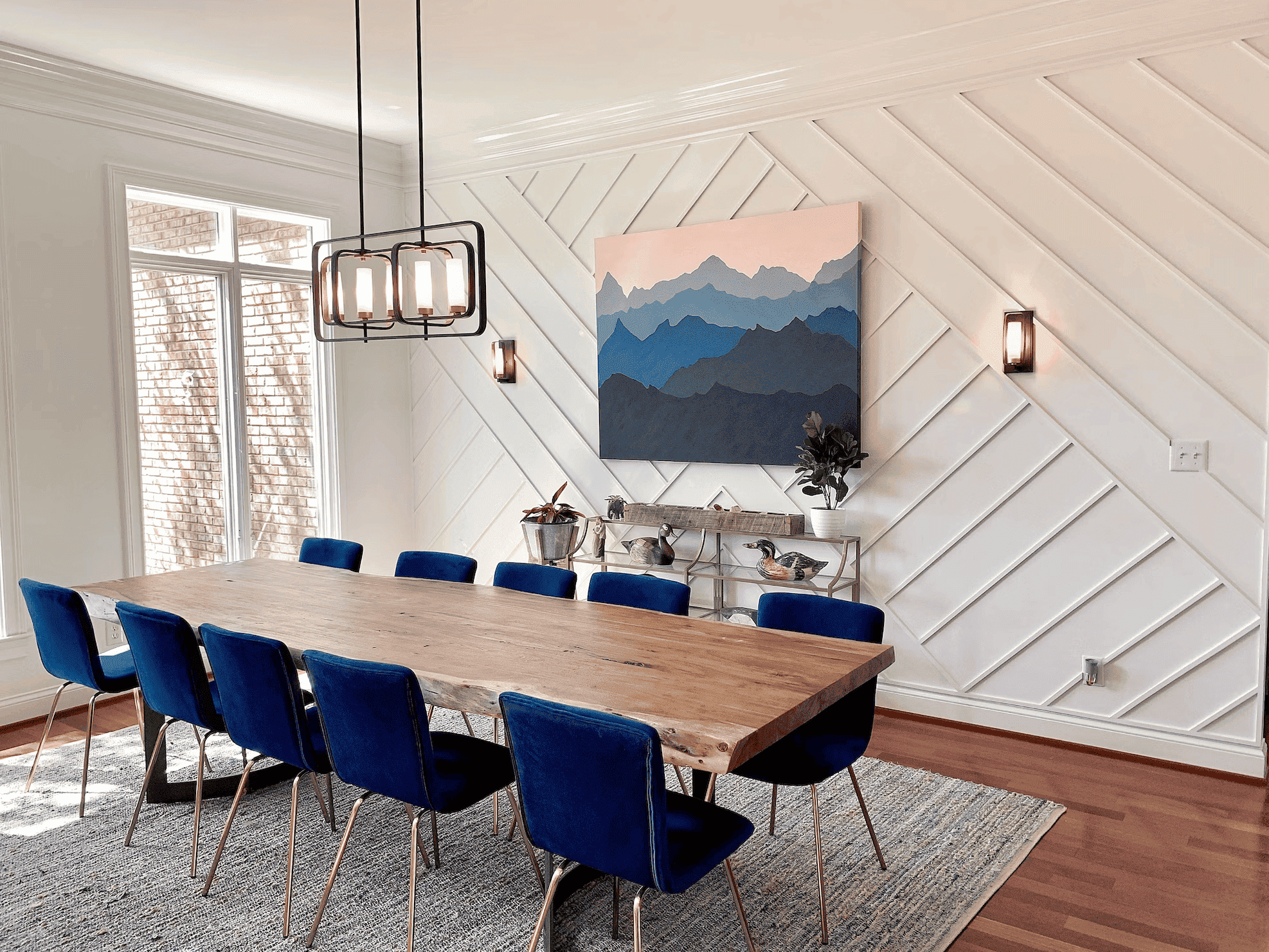

Particle board finds extensive use in construction, furniture manufacturing, and interior design. In construction, it’s commonly employed for subflooring and roofing due to its structural integrity. In furniture making, particle board serves as a cost-effective core material for items like cabinets, shelves, and tables. Its smooth surface also makes it a favored choice for laminated countertops. In interior design, it can be used for wall paneling and decorative surfaces.

Composition

Particle board, also known as chipboard, consists of wood particles, such as wood chips, sawmill shavings, or sawdust, bound together using adhesive resins. These wood particles are compressed and heated to form dense panels of varying thicknesses. The result is a sturdy and economical alternative to solid wood.

Applications

Particle board finds extensive use in construction, furniture manufacturing, and interior design. In construction, it’s commonly employed for subflooring and roofing due to its structural integrity. In furniture making, particle board serves as a cost-effective core material for items like cabinets, shelves, and tables. Its smooth surface also makes it a favored choice for laminated countertops. In interior design, it can be used for wall paneling and decorative surfaces.

- Wood Base Plain Particle Board

- Benefits

- Product & Specifications

Affordability: Particle board is notably more budget-friendly than solid wood, making it an excellent choice for cost-conscious projects.

Uniformity: Its composition ensures uniform density and thickness, reducing the risk of warping or twisting common in solid wood.

Smooth Surface: Particle board provides a smooth and even surface that is ideal for veneers, laminates, or paint finishes.

Environmental Friendliness: Many particle boards are manufactured using recycled wood and sustainable forestry practices, contributing to reduced waste and environmental conservation.

Versatility: Its adaptability to various finishes and easy machinability make it a versatile material for creative design solutions.

Environmental Considerations: While particle board has eco-friendly potential, its production involves the use of adhesives, which can emit volatile organic compounds (VOCs). However, modern manufacturing processes increasingly focus on low-emission adhesives, reducing its environmental impact. Additionally, sourcing particle board from sustainable forestry practices mitigates deforestation concerns.

In conclusion, particle board stands as a valuable resource in industries ranging from construction to furniture manufacturing. Its composition, cost-effectiveness, and versatility make it an attractive choice for a wide array of projects. With ongoing advancements in eco-friendly production methods, particle board is poised to remain a sustainable and practical solution for the future.

| Type of Particle Board | Wood Base Particle board |

| Type of Laminate | BSR / BSL / OSL / OSR |

| Thickness (in MM) | 9.00 / 12.00 / 17.00 / 25.00 |